快盈IV南方泵业股份有限公司(简称南方泵业)成立于1991年,中金环境(股票代码:300145)全资子公司,是集全球领先节能泵研发、制造、销售于一体的国有控股企业。

Company profile of Nanfang Pump Industry Co., Ltd.

快盈IV南方泵业股份有限公司(以下简称南方泵业),无锡市市政公用产业集团成员,是南方中金环境股份有限公司(创建于1991年,于2010年12月9日在深圳交易所发行上市,股票代码“300145”)子公司,是全国较早研发并规模化生产不锈钢冲压焊接离心泵、海水淡化高压泵的企业。

快盈IVAdvantages of technology are the origin of our company's continuous development.

三大国际化先进研发中心

快盈IV集合欧美先进研发技术,由位于西欧最先进的的工业设计理念,由位于北美的研发中心融合美洲现代化产业集群的生产经验,由位于中国杭州的中国研发中心打造最高效节…

智慧工厂

快盈IV南方泵业应用信息化技术打造了属于自身的智慧工厂,率先引进SAP资源管理系统,并成为杭州市“机器换人”重点建设项目落地单位之一,推动了信息化与工业化的深…

国家级企业技术中心

南方泵业股份有限公司(以下简称“公司”)技术中心被认定为第22批国家认定企业技术中心,国家级企业技术中心是我国企业技术中心评定级别的最高等级,由国家多个部…

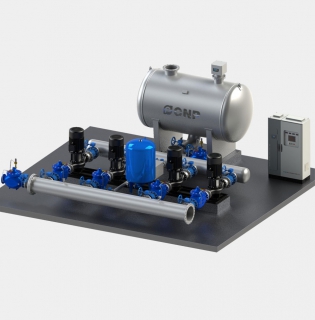

快盈IV工业级RAM架构数字集成系统

数字集成化智能控制技术,打造国内先进M2M模式,智能控制技术。智能稳流调节系统运用压差监测技术多级PID智能调节稳定控制进水流量大小保障市政管网安全智能…

We have established service network for our clients.